For PCB (Printed Circuit Board) repair, heat management is critical. Excessive or misdirected heat can lead to component failure, solder joint defects, or even irreparable damage to the board. For technicians and engineers, avoiding heat damage is not just a best practice—it’s a necessity.

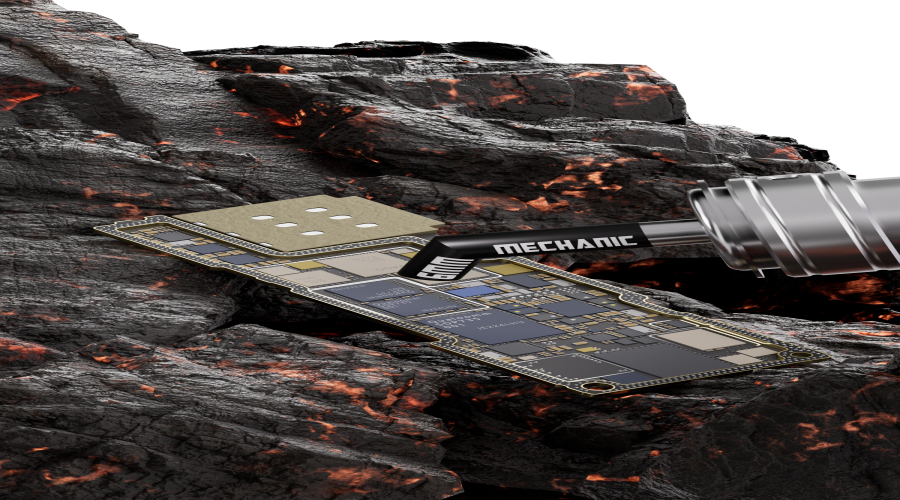

This is where specialized hot air nozzles come into play. These tools provide the precision and control needed to ensure safe, effective repairs.

2. Understanding Heat Damage in PCB Repairs

What Is Heat Damage?

Heat damage occurs when sensitive PCB components or solder joints are exposed to excessive or uneven heat during rework or repair. Symptoms include:

Burned or scorched components.

Warped or delaminated PCB layers.

Oxidized or brittle solder joints.

Causes of Heat Damage:

Overheating: Excessive temperatures applied for too long can damage components and PCB traces.

Imprecise airflow: Misdirected heat spreads to unintended areas, affecting nearby components.

Inconsistent heating: Uneven application of heat causes solder joints to fail or compromise.

By controlling airflow and temperature more effectively, specialized hot air nozzles can mitigate these risks and ensure better outcomes.

3. The Role of Specialized Hot Air Nozzles

Hot air nozzles are designed to focus and direct the airflow of a hot air rework station, providing precision and control. Here’s why they’re indispensable in PCB repairs:

Precision Heating: Nozzles allow heat to target specific areas, such as individual solder joints or small FPC connectors, without affecting surrounding components.

Versatile Designs: Options like 45° inclined nozzles or bent curved nozzles improve accessibility to hard-to-reach areas and make repairs under a microscope easier.

Even Heat Distribution: High-quality nozzles ensure uniform airflow, preventing hotspots and reducing the risk of localized overheating.

Reduced Airflow Spread: Nozzles with rounded or angled designs minimize the risk of heat blowing onto adjacent components, protecting the overall board integrity.

4. Choosing the Right Hot Air Nozzle for Your Repair Task

Selecting the right nozzle depends on the specific task at hand.

Small Solder Joints or FPC Repairs: Use narrow, pointed nozzles or 45° angled designs for focused heat application.

BGA Rework: Choose wide, circular nozzles to ensure even heating across the entire component.

Hard-to-Reach Areas: Opt for bent or inclined nozzles to navigate around obstacles and work comfortably under a microscope.

Material Considerations: Look for heat-resistant steel nozzles that prevent air leakage and withstand long-term use.

Compatibility: Ensure the nozzle fits securely onto your hot air gun or BGA rework station for optimal performance.

5. Tips for Using Hot Air Nozzles Effectively

Set the Right Temperature and Airflow: Adjust your hot air station to the recommended settings for the components being repaired. A typical range is between 300°C and 350°C, with airflow set to avoid displacing small components.

Maintain Proper Distance and Angle: Position the nozzle at the correct angle (e.g., 45°) and distance (1-2 cm) to achieve even heating without damaging the board.

Use a Steady Hand: Avoid moving the nozzle too quickly, as this can result in uneven heat distribution.

Regularly Clean the Nozzle: Remove solder residue and oxidation buildup to ensure consistent airflow and prevent clogging.