New technology will help save money

Apple started using OLED screens with iPhone X back in 2017 and the tech offers some great benefits. And along with the advancement in screens, costs have also increased over the years to get them fixed.For example with the largest iPhone OLED screen in the iPhone 14 Pro Max, it’s now $379 to replace. That’s about 1/3 of the device’s total cost.

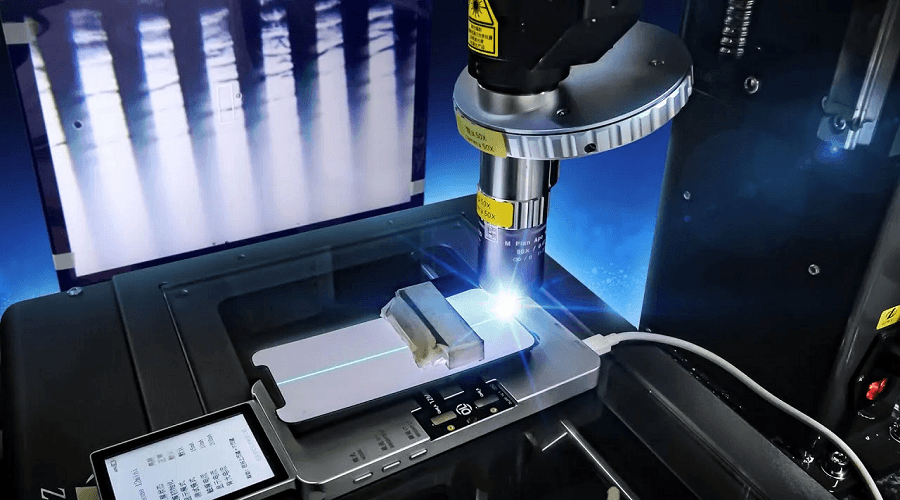

Now there’s a new technology that uses lasers to repair OLED screens without having to disassemble them. And it looks like it’s going to save a lot of time, money, and resources.

Revolutionizing Screen Repairs

Tools in New technologyEN-LS23 ITO Laser Machine: Direct Repair for OLED/LCD Display Screens

The EN-LS23 ITO Laser Machine is an impressive device specifically designed for repairing various issues in mobile phone display screens, including COP lining, COP, COF ear, and OLED corrosion.

EN-580SE Flex Cable Bonding Machine: Versatile Tool for LCD Repair

Another remarkable tool is the EN-580SE. It revolutionizes screen refurbishment by providing the ability to bond any mobile phone model, including those with marginal screens, OLED screens, TFT screens, and green cables.

With its advanced technology, the EN-580SE has the potential to transform the screen repair industry, saving users the hassle and cost of purchasing new smartphones.

How the Laser Repair Process Works

In Strange Parts video, the repair process using laser technology is explained. OLED panels have tiny traces that carry electrical signals across the display. When these traces are damaged, visible lines or display issues occur.

Advantages and Capabilities

One notable advantage of the EN-LS23 ITO Laser Machine is its ability to repair screens without disassembling them. This allows technicians to visually monitor the repair process and instantly recognize when the issue has been resolved.Additionally, the machine can adjust the attached flex by bending it as necessary, providing flexibility during repairs. The laser technology ensures meticulous repair of each trace until the screen lines disappear.

Limitations

It is important to note that this technology cannot repair physically damaged iPhone screens with cracks or scratches. The repair process is specifically designed for OLED panels fused to the glass.For physically damaged screens, alternative repair methods or screen replacements may be required.

To Conclude

The laser technology for OLED iPhone screen repairs is a game-changer in the industry. With the EN-LS23 ITO Laser Machine and EN-580SE Flex Cable Bonding Machine, technicians have efficient and cost-effective tools for addressing screen issues.As it becomes more accessible, it has the potential to revolutionize OLED screen repairs, benefiting users and the mobile phone industry.

You can check the video below to see how the laser machine can repair OLED panels and flex cables.

China Phonefix, a leading provider of mobile phone repair solutions, offers two cutting-edge tools that are revolutionizing the screen repair industry: the EN-LS23 ITO Laser Machine and the EN-580SE Flex Cable Bonding Machine.

1 comment

albert

Tool for LCD Repair