Regular Cleaning and Maintenance:

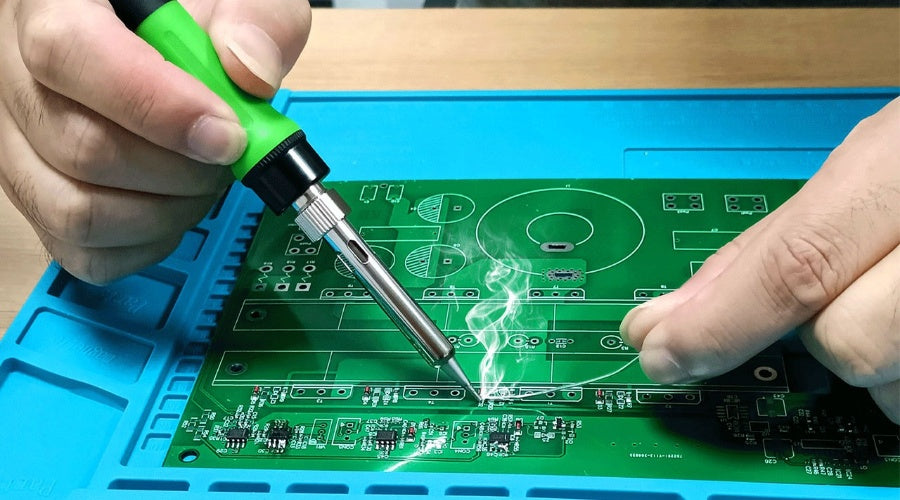

Soldering Tip Care: Regularly clean the Soldering Tip using a damp sponge or brass wool to remove oxidation and excess solder. Avoid abrasive materials like sandpaper that can damage the tip's plating. Tinning the tip by applying a small amount of solder before and after use helps protect it from oxidation and ensures good thermal conductivity.

Heater Cartridge Maintenance: Clean heater cartridges with a damp cloth and dry them thoroughly before reinstalling to ensure efficient heat transfer.

Temperature Management:

Appropriate Temperature Settings: Use the lowest temperature necessary for your task to reduce wear on the tip and prevent oxidation. For most tasks, a temperature range of 330℃ to 350℃ is recommended. Avoid prolonged exposure to high temperatures.

Advanced Temperature:

Control: Utilize soldering stations with temperature regulation features to maintain consistent heat levels, which helps in prolonging tip life.

Use of Quality Materials:

High-Quality Solder and Flux: Use Lead-free Soldering Paste or rosin-core solder for better flow and reduced oxidation. High-quality materials help maintain the soldering iron and ensure strong joints. Use flux to clean surfaces before soldering, but avoid excessive use as it can be corrosive.

Proper Storage and Handling

Storage Practices: Always place the soldering iron in a stand when not in use to prevent accidental burns and damage to the tip. Allow the soldering iron to cool completely before storing it.

Careful Handling: Soldering Station Handle is the soldering iron and station important connection parts with care to prevent physical damage. Avoid dropping or mishandling the equipment, which can cause internal damage or component failure.

Routine Inspections and Calibration:

Regular Inspections: Periodically inspect the soldering station for any signs of wear, loose connections, or damage. Address any issues promptly to prevent further damage or compromised performance.

Calibration: Regularly calibrate the temperature settings using a reliable thermometer or temperature probe to ensure precise soldering.

Points to note:

First, make sure the temperature of the soldering station is adjustable to suit different welding tasks.Second, choose the right soldering tools and heads to improve the accuracy and efficiency of welding.

In addition, safety is the top priority, avoid direct contact with the welding head to prevent burns, and ensure that the working area is clean and safe. Finally, the power supply should be turned off after use to avoid leaving it unattended for a long time to prevent fire hazards.

We firmly believe that if you have completed the above maintenance and precautions, the life of your soldering station will be extended. If your soldering station needs a major overhaul, it is recommended that you replace it with a new one, which will be better. The new Smart QUICK TS11 Soldering Station is a good choice. Take action quickly, and protect your soldering station as soon as possible!