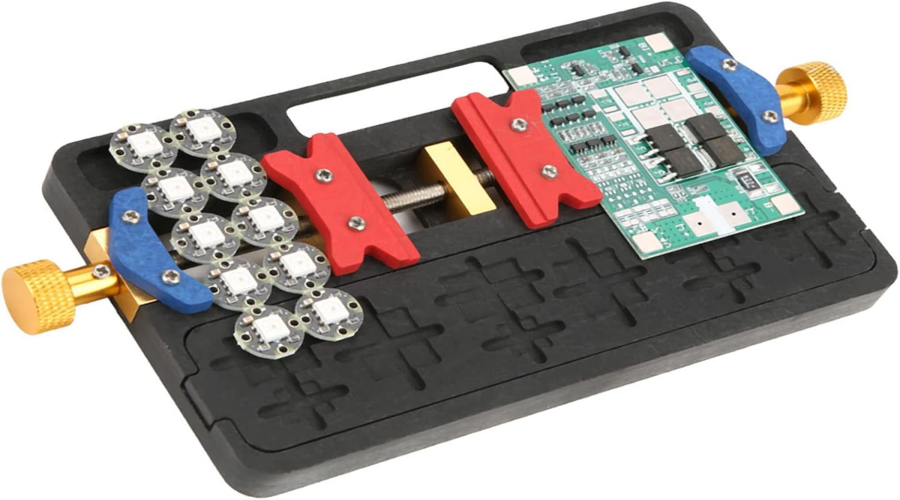

What Are Motherboard IC Clamps?

Motherboard IC clamps are specialized tools designed to securely hold smartphone motherboards, IC chips, and other delicate components during repair processes. Constructed with durable, high-temperature-resistant materials, these clamps often feature tempered glass panels, adjustable mechanisms, and compact designs. They are commonly used for chip clamping, soldering, glue removal, and various other precision repair tasks.

The Role of IC Clamps in Phone Repairs

1. Component Stability

During repairs, smartphone motherboards and chips must remain stationary to prevent accidental damage. IC clamps provide a stable platform, holding these components firmly in place. This stability is crucial for tasks such as soldering and cleaning, where even a slight movement can compromise the repair’s success.

2. Precision in Soldering

Soldering and desoldering are critical steps in repairing damaged ICs or installing new ones. Motherboard IC clamps ensure that components are perfectly aligned and securely fixed, allowing technicians to achieve clean and accurate solder joints. This reduces the risk of cold solder joints or misaligned connections, ensuring long-term reliability.

3. Glue Removal and Cleaning

Glue removal and cleaning are common tasks in phone repair, especially when dealing with adhesives used in shielding or IC packaging. The clamps keep the motherboard or chip steady, making it easier for technicians to remove residues without damaging the surrounding components.

4. IC Bonding and Packaging

In repairs requiring IC bonding or re-packaging, alignment is key. IC clamps enable technicians to accurately position chips onto the motherboard, ensuring a seamless fit. This enhances the durability and performance of the repaired device.

5. Testing and Debugging

During testing and debugging, motherboard IC clamps maintain a stable environment for electrical measurements and diagnostic processes. By reducing the risk of movement, they help ensure accurate readings and consistent results, ultimately leading to more effective repairs.

Key Benefits of Using Motherboard IC Clamps

1. Enhanced Precision: IC clamps stabilize components, enabling technicians to work with accuracy even on the smallest parts.

2. Reduced Risk of Damage: By securely holding components in place, clamps minimize the chances of accidental slips or misalignments.

3. Increased Efficiency: Tasks like soldering, cleaning, and glue removal become faster and easier with the aid of clamps.

4. Improved Safety: High-temperature-resistant materials protect both the tool and the technician during soldering and heating processes.

5. Versatility: Many IC clamps are compatible with a wide range of motherboard sizes and chip types, making them invaluable in any repair toolkit.

Tips for Choosing the Right IC Clamp

Durability: Opt for clamps made from high-quality, heat-resistant materials that can withstand prolonged use.

Adjustability: Look for models with adjustable features to accommodate various iPhone motherboard and chip sizes.

Ease of Maintenance: Transparent glass clamps with smooth surfaces are easier to clean after use.

Compatibility: Ensure the clamp is designed for the types of devices you frequently repair.