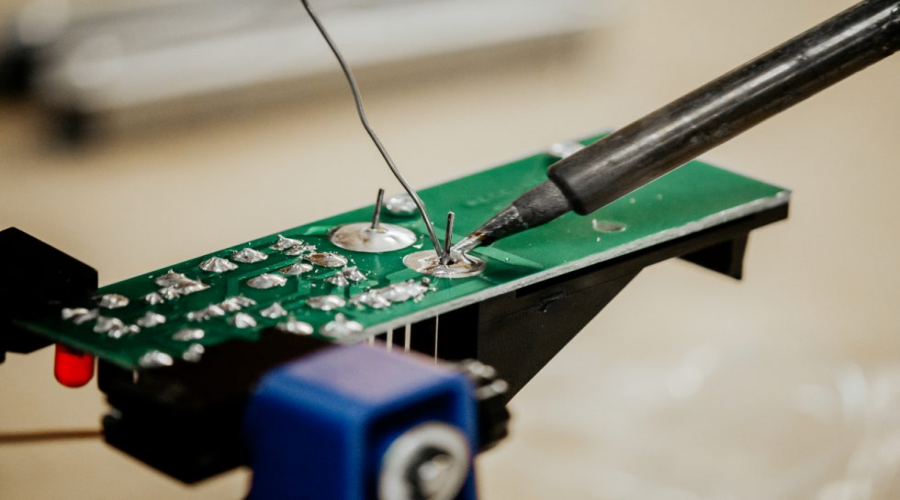

Soldering is a cornerstone of electronic repairs, especially in smartphone maintenance, where precise and reliable connections determine the success of a repair. However, achieving high-quality soldering depends not only on technique but also on the condition and use of soldering iron tips.

1. Common Soldering Problems and Symptoms

Soldering issues often arise during repair processes, leading to unreliable results. Below are the most prevalent problems and their symptoms:

Cold Solder Joints: The solder doesn’t fully melt, resulting in weak, unstable connections. Symptoms include intermittent functionality or no connection at all.

Dry Joints: Poor surface adhesion leads to incomplete bonding. Dry joints often appear dull and grainy.

Overheating Damage: Excessive heat can scorch PCBs or damage components, identifiable by discoloration or burned traces.

Solder Bridging: Excess solder accidentally connects adjacent points, causing short circuits, especially in dense circuit areas.

Oxidized or Contaminated Tips: A dirty or oxidized soldering tip impedes heat transfer and prevents solder from adhering properly.

2. Analyzing the Root Causes of Poor Soldering

To address these problems effectively, it’s crucial to understand their underlying causes:

Inconsistent Temperature Control: A soldering iron that’s too hot or too cold can lead to improper solder flow, overheating, or weak bonds.

Tip Deterioration: Over time, soldering tips become oxidized or clogged with residue, reducing heat conductivity and solder adhesion.

Improper Tool Selection: Using the wrong tip shape or size can lead to uneven heating and imprecise soldering.

Operator Errors: Insufficient training, excessive pressure, or incorrect angles can compromise the quality of a solder joint.

Low-Quality Materials: Poor solder or flux results in inconsistent melting, weak adhesion, and higher repair failure rates. Instead, high quality solder paste is needed.

3. Solutions for Common Soldering Issues

For each problem, there are targeted solutions to ensure reliable and professional results:

3.1 Fixing Cold and Dry Joints

Use a temperature-controlled soldering station to maintain consistent heat.

Clean the soldering tip regularly to ensure optimal heat transfer.

Preheat components and apply flux to improve solder flow.

3.2 Preventing Overheating Damage

Set your soldering iron to an appropriate temperature (350°C for general use).

Use a heat sink or thermal tape to protect nearby components.

Minimize soldering time to reduce heat exposure.

3.3 Avoiding Solder Bridging

Use a fine-point soldering tip for precision work on dense circuits.

Apply solder sparingly, focusing on accuracy rather than speed.

Employ desoldering tools, such as solder wick or a pump, to remove excess solder.

3.4 Maintaining Clean and Efficient Tips

Wipe the tip on a damp sponge or brass cleaner frequently during use.

Re-tin the tip by coating it with solder after each use to prevent oxidation.

Replace heavily worn or damaged tips to maintain performance.

4. Advanced Tips for Professional-Grade Soldering

To elevate your soldering skills, consider these advanced strategies:

Invest in High-Quality Tools: Use premium soldering stations with precise temperature controls and interchangeable tips to handle various tasks.

Optimize Your Workspace: Ensure adequate lighting, magnification, and ventilation for safe and efficient soldering.

Master Proper Techniques: Practice maintaining a 45°–60° angle, applying minimal pressure, and ensuring even heat distribution for consistent results.

Use Quality Materials: Select lead-free solder and reliable flux to achieve strong, clean connections.

5. Preventative Measures to Avoid Future Issues

Consistent soldering quality depends on proactive maintenance and preparation:

Regular Tip Maintenance: Clean and inspect soldering tips frequently to prevent residue buildup or oxidation.

Store Tools Properly: Keep soldering equipment in a clean, dry environment to extend its lifespan.

Train Regularly: Stay updated on new techniques and tools from China Phonefix to refine your skills and handle emerging challenges in electronics repair.

Common Issues with Soldering Iron Tips and How to Fix Them

Diyfixtool Ci

Popular posts

-

How to Slove with Charging Paused Battery Temperature too Low?Battery TemperatureSep 16, 2024

How to Slove with Charging Paused Battery Temperature too Low?Battery TemperatureSep 16, 2024 -

How to Resolve iPhone Non-Genuine Battery Pop-up with i2C KC02S?Battery Pop-upMar 06, 2024

How to Resolve iPhone Non-Genuine Battery Pop-up with i2C KC02S?Battery Pop-upMar 06, 2024 -

-

7 Ways To Fix Charging Stopped Phone Temperature Is Too LowCharging IssueMay 20, 2022

7 Ways To Fix Charging Stopped Phone Temperature Is Too LowCharging IssueMay 20, 2022 -

Cell Phone Repair Technician's Workstation Setup Ideas & ToolsPhone Repair BusinessDec 23, 2023

Cell Phone Repair Technician's Workstation Setup Ideas & ToolsPhone Repair BusinessDec 23, 2023

PHONEFIX HOT SALE

PHONEFIX

PHONEFIX Polish Grinding Pen PCB Board BGA Chip Removing Repair

Sale priceFrom $0.99 USD

Regular price$2.59 USD

In stock

PHONEFIX

AIFEN A9 Plus Digital Display Soldering Station With T210/245/115 Handle

Sale priceFrom $75.55 USD

Regular price$86.99 USD

In stock

PHONEFIX

188W GaN Charger Phones Laptops PD3.1 Fast Charging Station

Sale price$35.99 USD

Regular price$38.99 USD

In stock