LCD lamination is a crucial step in phone repair, especially when restoring cracked screens or replacing display components. The lamination process ensures a smooth, seamless bond between the LCD and the glass, giving the repaired phone a flawless, factory-like appearance. One of the main decisions that repair technicians face is whether to invest in an all-in-one laminating machine or opt for a setup with separate air and vacuum pumps. Both have their advantages, but which one is right for your repair shop?

2. What is an All-in-One LCD Laminating Machine?

An all-in-one LCD laminating machine is a single device designed to handle multiple functions required for screen lamination, including:

Vacuum pumping to remove air bubbles.

Laminating the LCD with precise pressure.

OCA bonding to adhere the optical clear adhesive between the LCD and the glass.

Bubble removal using built-in autoclave functionality.

These machines are highly automated, requiring minimal user intervention. They streamline the repair process by combining all essential functions into one unit. Their ease of use, compact design, and efficiency make them ideal for smaller shops or technicians looking to simplify their workflow. With minimal setup and fewer moving parts, an all-in-one machine ensures a seamless, professional finish with less effort.

Advantages of an All-in-One Machine:

Space-Saving: A single unit that fits in even the smallest repair spaces.

Simplified Operation: User-friendly interfaces and pre-set options make it accessible even for beginners.

Time-Efficient: Automation reduces time spent on each repair.

Lower Maintenance: With fewer components, there’s less risk of malfunction and easier maintenance.

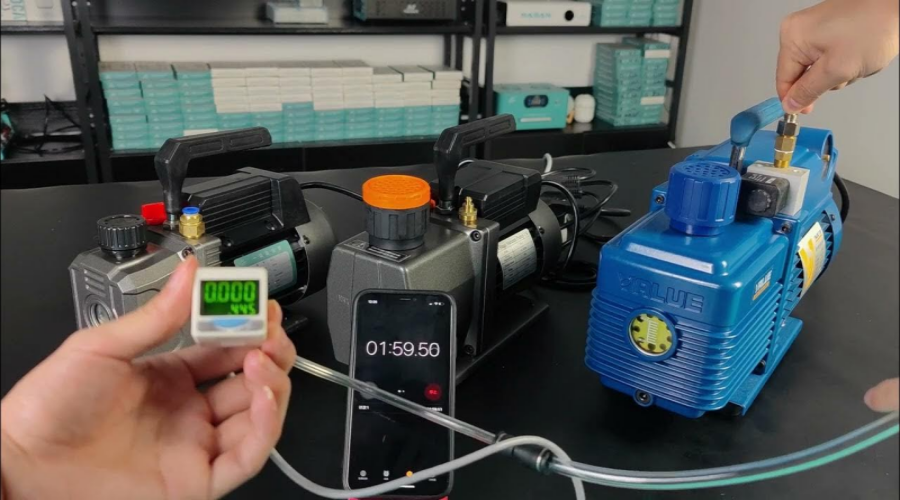

3. What Are Separate Air and Vacuum Pump Machines?

A setup with separate air and vacuum pumps involves using standalone machines for different stages of the lamination process. Typically, you’ll have:

A vacuum pump that creates a vacuum environment to eliminate air bubbles from the lamination.

An air compressor that applies the necessary pressure to bond the LCD and glass.

A laminator for applying heat and bonding the materials.

This method gives repair technicians more control over each step of the lamination process and often provides more powerful performance for high-volume shops or more complex repair needs. However, the added complexity comes at the cost of space, setup time, and maintenance.

Benefits of Separate Machines:

Customizable: You can select specialized equipment suited to specific repair needs.

Powerful: Separate machines often offer stronger performance, suitable for high-demand environments.

Greater Flexibility: Technicians can adjust each stage of the process for optimal results.

Scalable: As your shop grows, you can upgrade or add to your system.

4. Comparing Performance and Usability

Ease of Use:

All-in-One Machine: These machines are straightforward, with pre-programmed functions and simple setups, making them ideal for beginners or small shops with limited technical knowledge.

Separate Machines: While more powerful, using separate machines requires more technical expertise. Operators need to coordinate multiple machines and settings for each repair step, which can lead to a steeper learning curve.

Precision and Efficiency:

All-in-One Machine: Offers reliable, consistent results with minimal input. Automation ensures each repair is performed the same way, reducing the risk of human error.

Separate Machines: Technicians have more control, allowing for fine-tuning and customization, which can be beneficial for advanced repairs. However, this also means the process can take longer and require more skill.

Cost:

All-in-One Machine: Usually more cost-effective in the short term, as you’re buying a single device with all necessary functions included.

Separate Machines: Initial costs can be higher because you need to invest in multiple devices. However, the long-term benefits, especially in high-volume repair shops, may offset the initial investment.

Space Requirements:

All-in-One Machine: Compact and ideal for repair shops with limited space.

Separate Machines: Requires significantly more space to house each component, which may not be suitable for smaller operations.

5. Which Option is Right for You?

The choice between an all-in-one LCD laminating machine and a separate air and vacuum pump setup depends on your specific needs:

For small repair shops or beginners, an all-in-one machine is a great option. It’s affordable, easy to use, and takes up minimal space, making it an excellent choice for those just starting out or those who don’t need advanced customization.

For larger repair shops or experienced technicians, separate machines may offer more value. The ability to fine-tune each step of the lamination process and the power of separate machines(including LCD Laminator Machine) can make a significant difference in high-volume or complex repairs.

7. Conclusion

Whether you choose an all-in-one LCD laminating machine or separate air and vacuum pumps, both options have their benefits. It ultimately comes down to your repair needs, space availability, and technical expertise. For simplicity and efficiency, an all-in-one solution will likely serve you well. However, for those seeking more control and flexibility, separate machines may provide the precision and power necessary to elevate your repair business.There' so many choices here in China Phonefix. You can choose from a wide range of Screen Refurbishing Machines to suit your needs.

All-in-One LCD Laminating Machine vs. Separate Air and Vacuum Pump